Olive oil

Follow the journey from olive grove to olive oil

The majority of olive harvests occur in the final few months of the year and we have dedicated this page to taking you through the intricate journey from olive grove to olive oil. Producing quality olive oil year after year takes experience, passion and dedication as well as careful coordination between farmer, nature and processing plant. Olive farming and olive oil production are usually a community co-operative effort where everyone is invested in a sustainable and successful outcome.

Growing olives:

Olive trees are ideally suited to Mediterranean climates, with cool rainy winters and hot dry summers. Their leaves' underside have a distinctive silver coating that prevents water loss, and their shallow roots can collect water from fast-draining soil. A young olive tree starts to bear fruit at 5 years old, reaching peak production at 10 years and continuing to bear fruit for millennia. One tree can yield an average of 20-50kg of olives or around 3-7 litres of olive oil per harvest. Farmers make sure their trees are properly pruned, nourished and irrigated.

After winter pruning and throughout Spring tiny white buds start to grow, and the earlier they blossom the more olives will likely be produced. In late Spring the flowers bloom, and the fertilised ones will reveal the tiny green olive fruit growing inside them. The olive will grow throughout the summer and reach full size just as the seasons start to change.

As summer draws to a close, rainfall, cooling temperatures and shorter days provide cues for the olive to begin to ripen. All olives start off life as green and turn purple as they ripen. This colour change is a signal to birds and other creatures that the fruit is edible, a natural mechanism to disperse the olive pits, which contain the olive tree's genetic material, to find new soil and to create new trees.

The harvest:

The decision of when to harvest is determined by a few factors such as the required flavours of olive oil, the weather and availability of the processing plant. Early harvest mixed green/purple 'veraison' olives produce fruity and peppery tasting oil that is greener in colour. Late harvest more ripened dark purple olives produce slightly sweeter, more yellowish oil that contains lower levels of antioxidant polyphenols.

Harvest methods on smaller farms involve picking olives by hand or by rake, or using handheld motorised rakes and branch shakers. Larger farms use small vehicles that shake the tree by its trunk or combine harvesters that whack the olives off branches with spinning rods. Whichever technique is used, great care must be taken not to bruise the olives during harvest or transport to the processing plant.

The picked olives are also sensitive to heat, light and oxygen, all of which can cause degradation with time, so they must be brought to the processing plant as soon as possible, usually in the same day and ideally within hours.

Processing:

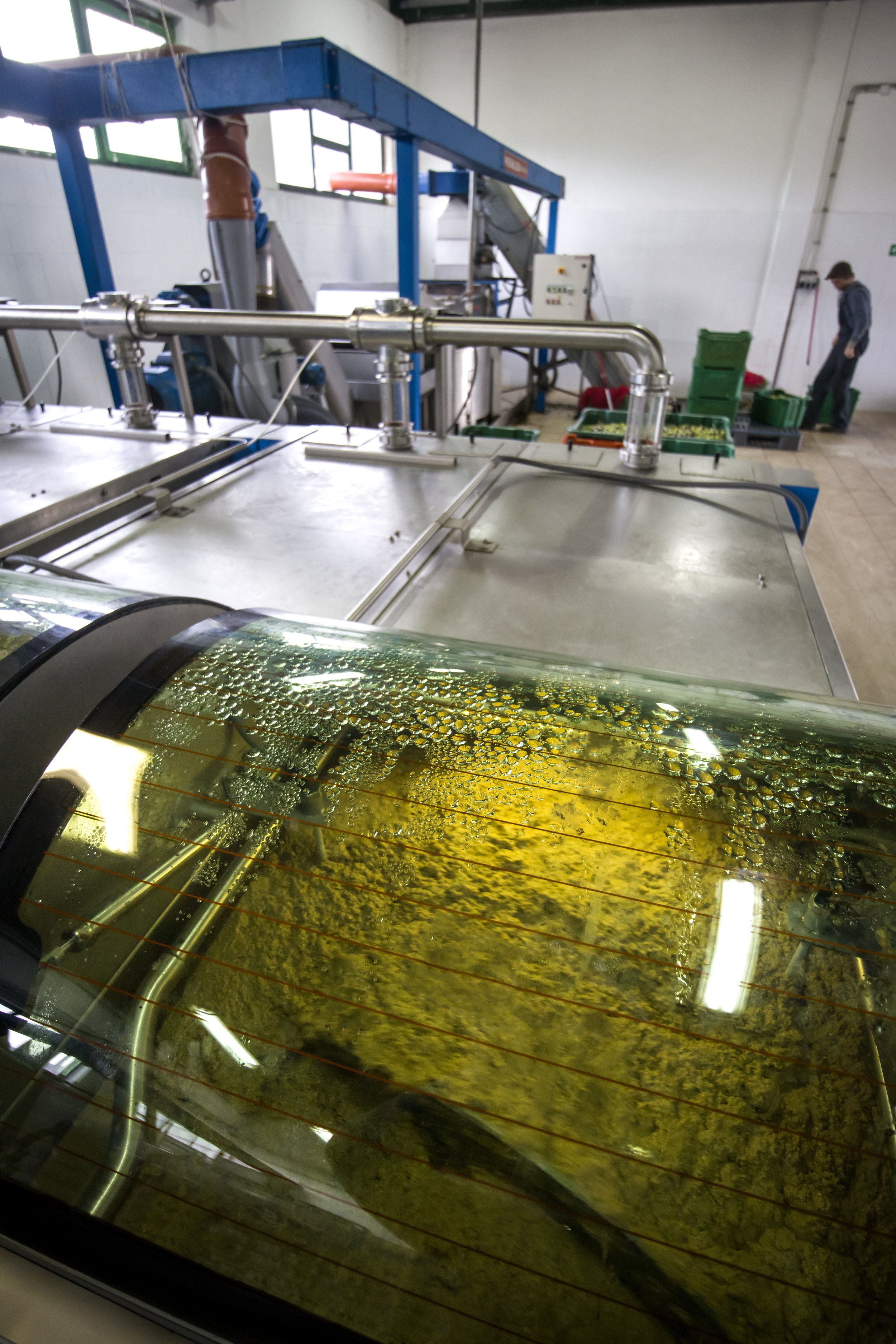

During harvest season processing plants can operate round the clock to ensure harvested olives are processed as quickly as possible.

The olives need to be separated from the leaves and twigs and washed in water.

Traditional mills use grindstones to crush the olives and mix the olive paste, which is then placed in fibrous discs that are stacked and pressed to extract the oil. In modern mills this process is more integrated and is done by controlled machinery.

In the first stage the olives are pressed and crushed into a paste, releasing the oil from their microscopic vacuoles. The next stage is mixing or 'malaxation' of the olive paste, which further breaks down the cells and activates enzymes to create aromatic and phenolic compounds. This stage generates heat, so it's critical to keep the temperature below 35c to protect the nutrient value of the emerging oil.

The mixture of solids and liquids then enters a centrifuge where the paste, water and pits are separated from the oil, which is then left to settle. This oil tastes almost like fresh fruit juice, and anyone lucky enough to try it will experience incredible aromas, notes and flavours. It does still contain some water and after settling this separates and can be easily drained off, leaving pure olive oil.

Prior to bottling, olive oil is often stored in stainless steel containers to protect against heat and light, and they are topped off with nitrogen to protect against the effects of oxygen on the oil.

Not letting anything go to waste, the leftover solids can be dried and used as feed for livestock, and in earlier times this was even used for lighting and heating.

Thank you for joining us on this intricate and fascinating journey from olive grove to olive oil. Next time you enjoy olive oil on your salad or in your skincare routine you’ll know a bit more about how it got there.